Technology

Manufacturing Technology

Manufacturing processes for quality productsWe understand the demands of our end-users and have been delivering quality products to them. Our manufacturing processes utilize modern technology and machineries that meet the international standards. Through meticulous manufacturing processes and care from the experts, the products are made to the satisfaction of the end-users.

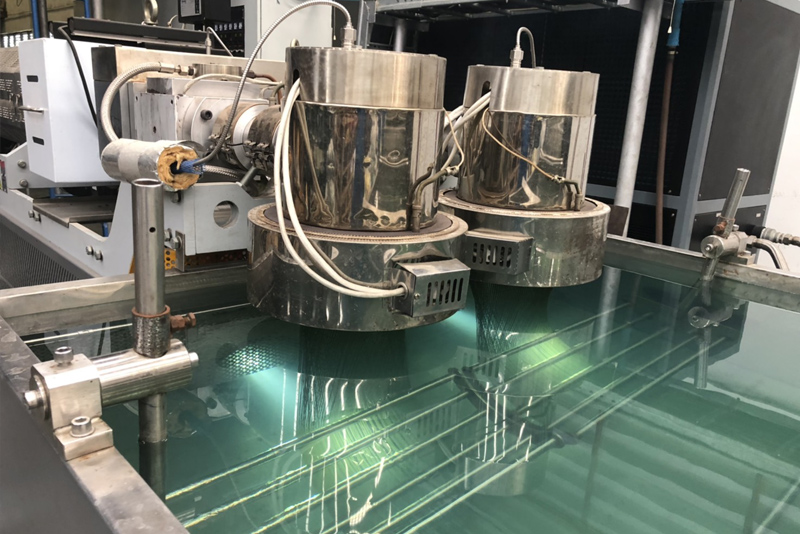

Raw materials mixing process

Material mixing is a process of combining and averaging different raw materials by mixing them into required conditions. The materials are mixed by spinning blades in an open or closed tank to crush and satirize until the substances mixed well. There are many types of mixing machines suitable for the kind and size of plastic.

01

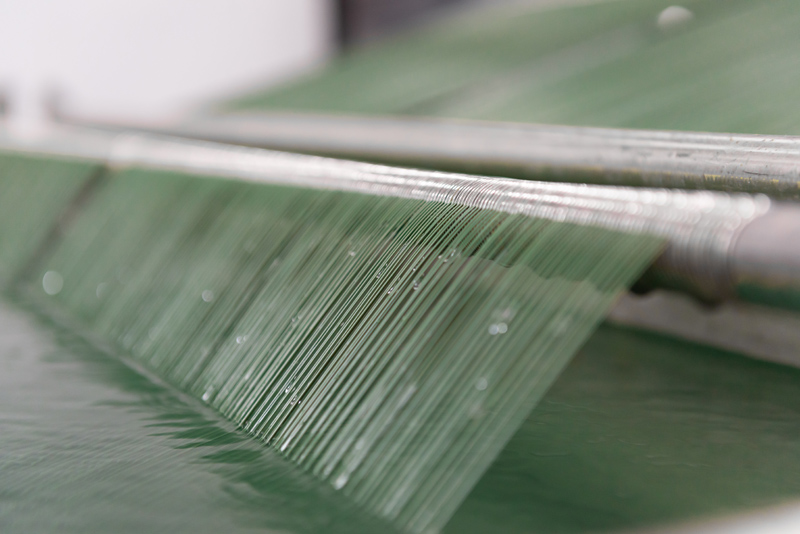

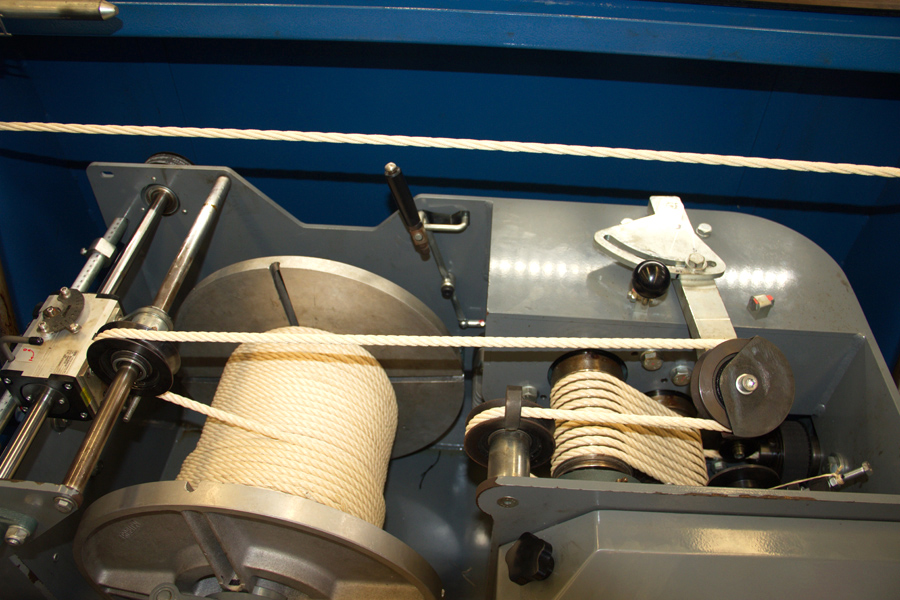

Twisting process

The thread twisting process is a process of combining the yarn by twisting them into the rope with the required size and number of filaments by controlling the number of threads per meter (TPM) to form sufficient strength for the use. This process is done by using a twisting machine or rope machine.

03

Weaving process

Weaving Process is a process of taking twisted 2-ply and 3-ply ropes to the net weaving machine to produce nets with varieties of width and length in accordance with end-user needs. The weaving machine has a panel of spool thread and bobbin thread, both of which tie and form meshes and the space of the mesh is set. The net width depends on the numbers of bobbin used that varies with the size of the mesh and the length depends on the long side of the knot weaved.

05

Baking process

Nets Heat Setting 1 and Quality Inspection Check processes apply for the YOKO net only. This process is baking and stretching in a depth wise direction. The baking process (Heat Setting1) is done by stretching the net to achieve a standard size in the horizontal baking machine, close the machine door, let hot air into the machine for a specific time until the net set well. The final step is quality checking, if a defect is found immediate repair is required before passing the product to the next process.

07

Quality inspection

09